Belajar SAP 2000, Staad Pro dan ETABS untuk Perhitungan Struktur Gedung dan Atap Baja Ringan Sabtu, 25 Juni 2016 Add Comment Edit Kemampuan penguasaan software perencanaan struktur terumata ETABS dan SAP 2000, Staad Pro sangat penting, terutama bagi para Engineer yang bergelut di Dunia konstruksi.

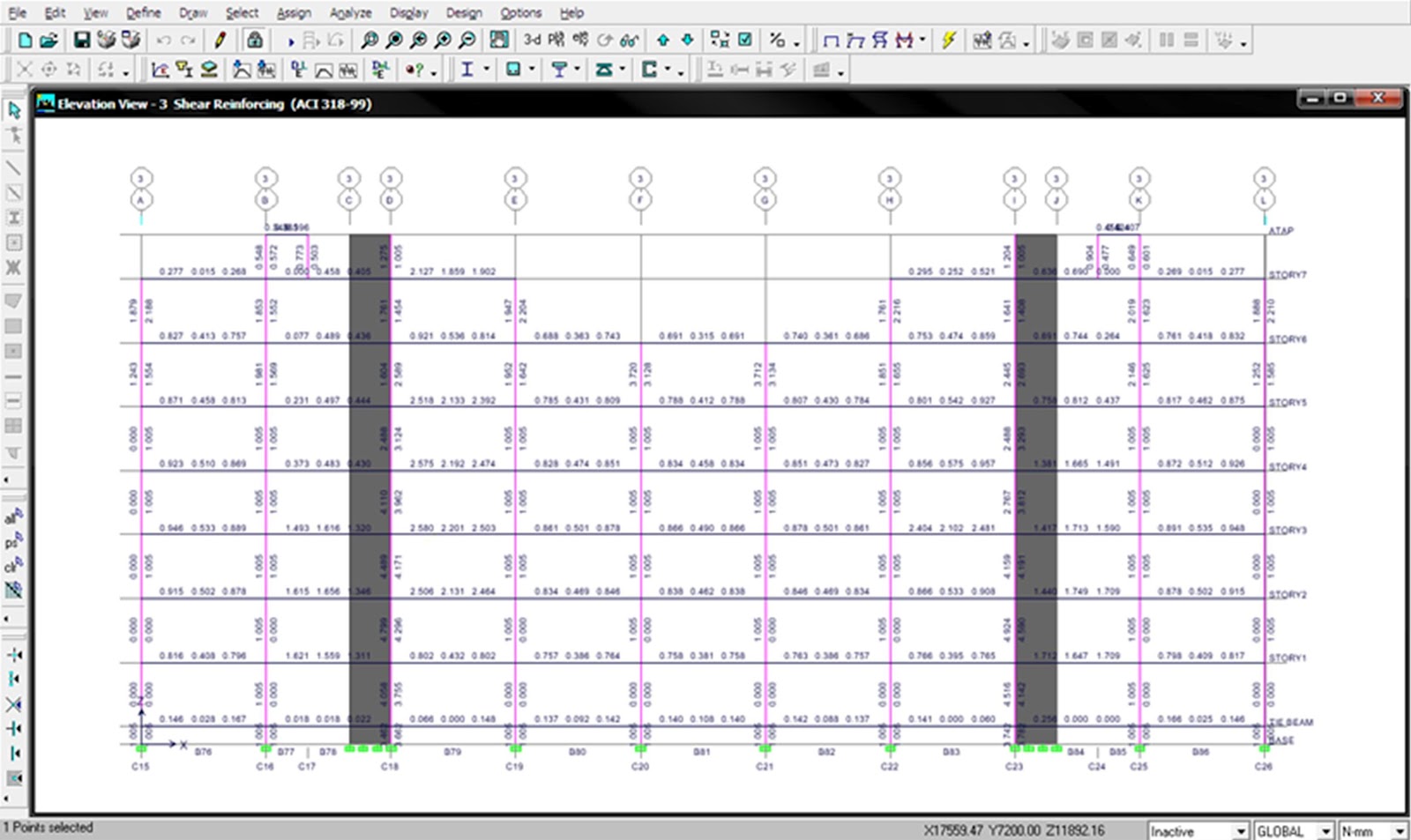

Analisis dinamik linier riwayat waktu (time history) sangat cocok digunakan untuk analisis struktur yang tidak beraturan terhadap pengaruh gempa rencana.Mengingat gerakan tanah akibat gempa di suatu lokasi sulit diperkirakan dengan tepat, maka sebagai input gempa dapat didekati dengan gerakan tanah yang disimulasikan. Perhitungan gempa dengan menggunakan etabs by rahmat7sidik. Ed = 1.0626 Koefisien gaya geser dasar gempa arah Y = C1 x I / R 0.25 7.514 = R 8.75 Atap. 46 599.51 ∑WxZ= 491290.18 Analisa Gempa Dinamik Time History A0 I 0.32.

SANSPRO V.4.7Program Komputer terpadu untuk pemodelan, analisis, disain, penggambaran, dan perhitungan volume dan biaya struktur gedung dan struktur lainnya. Untuk baja dan beton. Dapat input model dari Autocad dan menghasilkan gambar ke Autocad. Gambar 3D dalam format VRML dapat dihasilkan dengan cepat. Menggunakan multiple windows/views, garis as arah X,Y, construction lines, tersedia berbagai mesh generator. Disain fundasi footing dan tiang secara otomatis.

Sangat mudah digunakan dan terbukti lebih cepat 2x dari ETABS V.8.0 dalam keseluruhan proses dari awal sampai selesai (pengalaman di berbagai konsultan struktur di Jakarta yang telah terbiasa menggunakan ETABS V.8.0 dan pindah ke SANSPRO V.4.7)SOILAB V.3.1Program bantu laboratorium mekanika tanah yang populer untuk mengolah data lab soil dan mencetak grafiknya untuk laporan. Tersedia dalam versi database (semua data disimpan dalam database) dan nondatabase (data disimpan terpisah per file). Metoda AASHTO’93Salah satu metoda perencanaan untuk tebal perkerasan jalan yang sering digunakan adalah metoda AASHTO’93. Metoda ini sudah dipakai secara umum di seluruh dunia untuk perencanaan serta di adopsi sebagai standar perencanaan di berbagai negara. Metoda AASHTO’93 ini pada dasarnya adalah metoda perencanaan yang didasarkan pada metoda empiris. Parameter yang dibutuhkan pada perencanaan menggunakan metoda AASHTO’93 ini antara lain adalah:a. Structural Number (SN)b.

Lalu lintasc. Faktor lingkungane. Serviceablity1.1 Structural NumberStructural Number (SN) merupakan fungsi dari ketebalan lapisan, koefisien relatif lapisan (layer coefficients), dan koefisien drainase (drainage coefficients). Persamaan untuk Structural Number adalah sebagai berikut:SN = a1D1 + a2D2m2 + a3D3m3.(Pers. 1)Dimana:SN = nilai Structural Number.a1, a2, a3 = koefisien relatif masing‐masing lapisan.D1, D2, D3 = tebal masing‐masing lapisan perkerasan.m1, m2, m3 = koefisien drainase masing‐masing lapisan.1.2 Lalu LintasProsedur perencanaan untuk parameter lalu lintas didasarkan pada kumulatif beban gandar standar ekivalen (Cumulative Equivalent Standard Axle, CESA). Perhitungan untuk CESA ini didasarkan pada konversi lalu lintas yang lewat terhadap beban gandar standar 8.16 kN dan mempertimbangkan umur rencana, volume lalu lintas, faktor distribusi lajur, serta faktor bangkitan lalu lintas (growth factor).1.3 ReliabilityKonsep reliability untuk perencanaan perkerasan didasarkan pada beberapa ketidaktentuan (uncertainties) dalam proses perencaaan untuk meyakinkan alternatif‐alternatif berbagai perencanaan.

Tingkatan reliability ini yang digunakan tergantung pada volume lalu lintas, klasifikasi jalan yang akan direncanakan maupun ekspetasi dari pengguna jalan.Reliability didefinisikan sebagai kemungkinan bahwa tingkat pelayanan dapat tercapai pada tingkatan tertentu dari sisi pandangan para pengguna jalan sepanjang umur yang direncanakan. Hal ini memberikan implikasi bahwa repetisi beban yang direncanakan dapat tercapai hingga mencapai tingkatan pelayanan tertentu.Pengaplikasian dari konsep reliability ini diberikan juga dalam parameter standar deviasi yang mempresentasikan kondisi‐kondisi lokal dari ruas jalan yang direncanakan serta tipe perkerasan antara lain perkerasan lentur ataupun perkerasan kaku. Secara garis besar pengaplikasian dari konsep reliability adalah sebagai berikut:a. Hal pertama yang harus dilakukan adalah menentukan klasifikasi dari ruas jalan yang akan direncanakan. Klasifikasi ini mencakup apakah jalan tersebut adalah jalan dalam kota (urban) atau jalan antar kota (rural).b. Tentukan tingkat reliability yang dibutuhkan dengan menggunakan tabel yang ada pada metoda perencanaan AASHTO’93. Semakin tinggi tingkat reliability yang dipilih, maka akan semakin tebal lapisan perkerasan yang dibutuhkan.c.

Satu nilai standar deviasi (So) harus dipilih. Nilai ini mewakili dari kondisi‐kondisi lokal yang ada.

Berdasarkan data dari jalan percobaan AASHTO ditentukan nilai So sebesar 0.25 untuk rigid dan 0.35 untuk flexible pavement. Hal ini berhubungan dengan total standar deviasi sebesar 0.35 dan 0.45 untuk lalu lintas untuk jenis perkerasan rigid dan flexible.1.4 Faktor LingkunganPersamaan‐persamaan yang digunakan untuk perencanaan AASHTO didasarkan atas hasil pengujian dan pengamatan pada jalan percobaan selama lebih kurang 2 tahun.

Pengaruh jangka panjang dari temperatur dan kelembaban pada penurunan serviceability belum dipertimbangkan. Satu hal yang menarik dari faktor lingkungan ini adalah pengaruh dari kondisi swell dan frost heave dipertimbangkan, maka penurunan serviceability diperhitungkan selama masa analisis yang kemudian berpengaruh pada umur rencana perkerasan.Penurunan serviceability akibat roadbed swelling tergantung juga pada konstanta swell, probabilitas swell, dll. Metoda dan tata cara perhitungan penurunan serviceability ini dimuat pada Appendix G dari metoda AASHTO’93.1.5 ServiceabilityServiceability merupakan tingkat pelayanan yang diberikan oleh sistem perkerasan yang kemudian dirasakan oleh pengguna jalan. Untuk serviceability ini parameter utama yang dipertimbangkan adalah nilai Present Serviceability Index (PSI). Nilai serviceability ini merupakan nilai yang menjadi penentu tingkat pelayanan fungsional dari suatu sistem perkerasan jalan.

Secara numerik serviceability ini merupakan fungsi dari beberapa parameter antara lain ketidakrataan, jumlah lobang, luas tambalan, dll.Nilai serviceability ini diberikan dalam beberapa tingkatan antara lain:a. Untuk perkerasan yang baru dibuka (open traffic) nilai serviceability ini diberikan sebesar 4.0 – 4.2. Nilai ini dalam terminologi perkerasan diberikan sebagai nilai initial serviceability (Po).b. Untuk perkerasan yang harus dilakukan perbaikan pelayanannya, nilai serviceability ini diberikan sebesar 2.0. Nilai ini dalam terminologi perkerasan diberikan sebagai nilai terminal serviceability (Pt).c. Untuk perkerasan yang sudah rusak dan tidak bisa dilewati, maka nilai serviceability ini akan diberikan sebesar 1.5.

Nilai ini diberikan dalam terminologi failure serviceability (Pf). These pictures were taken in 1935 when one of the largest hydroelectric projects in US history was close to completion, Hoover Dam. The project was started in 1932 during the Hoover era and finished May 29, 1935 during the Roosevelt era.The dam planning stage started in 1920's to tame the mighty Colorado river. This project was primarily needed to alleviate the constant flooding of the Imperial Valley, regularly breaking manmade dikes and levies and ruining farmlands for years. In 1905 the river overflowed so much that it flowed over 50 miles to create the Salton Sea, filling what was once an ancient dry lakebed. Unfortunately man had been mining salt from this dry lakebed for years to provide salt to the LA area. The flooding of the salt mine eliminated LA's source for salt, and as a result this new body of fresh water turned salty, today 5 times as salty as the ocean!

Hence, the need to tame the Colorado river was of high importance to prevent future disasters. 15yrs later Hoover Dam was conceived.The site of Hoover Dam was very key for the project to hold one of the largest manmade bodies of water in the country. Near Boulder Canyon, the dam was originally called Boulder Canyon Dam.

The nearby down of Boulder City was created specifically to house and feed the workers that built the dam, not to mention manufacture many of the parts for the dam, like penstock pipes.Even by today's standards Hoover Dam was a gigantic project. At the time it was the worlds largest project made with concrete, not to mention the largest public works project in US history. Keep in mind there were no computers, this was all done on paper using a slide rule and pure ingenuity. It's an amazing engineering accomplishment.After years of planning the project began in the middle of the Great Depression. Workers were easy to find, pay was good for those times but the work was dangerous and very hot during the summer. Work occurred 24X7 to finish the project as soon a feasibly possible, and it was finished 2yrs ahead of schedule.

The first job was to divert the river which began in 1932. This was done by building two cofferdams to prevent flooding and divert water around the construction project using diversion tunnels. At the same time the diversion project was underway, the canyon walls were prepared to hold the new dam by clearing loose rocks with dynamite and bulldozers. Remnants from the canyon clearing aided the building of the cofferdams.Over the a total of 5yrs of construction (April 1931to March 1936) there was an average crew of 3500 men that worked on the project daily. Over this 5yr period there were over 21,000 individuals that worked on the dam. Monthly payroll during the 5 years for an average crew of 3500 was $500,000, or $140/mo per worker.Pouring thick concrete has it's own problems. The curing process of concrete creates heat.

Thick bodies of concrete cannot cure evenly, required for strength and integrity to prevent cracks. Another problem is the concrete needs to cure fast enough to stay on schedule. To address these problems the concrete was poured in 5ft thick sections with embedded cooling pipes that run water through the concrete to cool the concrete evenly and quickly. These 1' pipes are still in the dam concrete today, over 582 miles of pipe! But even today the concrete is still curing, harder and harder every year. 75yrs later.The dam is a whooping 725ft high, 2nd highest in the country.

The dam generators produce over 2000 megawatts of power from water turning might generator turbines. Besides the massive watershed and electrical power the dam generates, it also provides an incredible playground for boaters and fisherman. Lake Mead was named after the dam's project manager, Elwood Mead who was a legend in his own time with such an incredible engineering project, successfully done without computers!With the rugged working conditions, dangerous and hot, there were 112 lives lost from various reasons, such as accidents, heat stroke and heart failure. In the very beginning when work started there was a strike attempt which failed, but resulted in more attention to providing water hydration to workers on a regular basis.

Well duh!Originally deemed the Boulder Canyon Dam, in 1931 it was named Hoover Dam by Ray Wilbur, President Hoovers interior secretary. This was very controversial as Hoover was commonly blamed for starting the Great Depression. Later when Franklin Roosevelt became president in 1932 (before the dam was finished) it was renamed 'Boulder Dam' by Harold Ickes, FDR's interior secretary who disliked Hoover and his economic policies. In 1947 the dam was renamed 'Hoover Dam' by President Truman under pressure from Congress as the public forgot about President's Hoover's handling of the Great Depression.Hoover dam also served as a highway connector between Arizona and Nevada. A two lane highway on top of the dam used to handle 17,000 vehicles crossing the dam each day. As a result of 911 no heavy trucks are allowed to cross the dam.If you're visiting the area MAKE SURE you take the HOOVER DAM TOUR. It's the best dam tour in the West;-) You'll talk about the tour for years, seeing massive generators, pipes, and concrete objects, including a big bridge, all made by man.

It's truly and incredible dam that inspires people of all ages, sexes, religions and races. It's a must do tour. The economical visit includes FREE PARKING on the Arizona side of the dam. Have your most fit person volunteer to drive and drop others off at the tour center to wait in line for tour tickets.

Your volunteer walks the 1/2mi from the free parking lots to the tour center, about an 8min walk. Stay in touch with your cellphone. This little tip will save you time and money.If you haven't taken the dam tour before, it's a good prelude to visit the Alan Bible visitor center before you do so, it's free.

They have all kinds of information about Lake Mead and the surrounding areas to help you get oriented with your visitation plans. The visitor center is open from 8:30am to 4:30pm except Thanksgiving, when it's closed. Recently, the world’s largest solar-powered office building was unveiled in Dezhou, Shangdong Province in northwest China. The 75,000-square-meter office building bears a resemblance to an ancient sun dial and reminds visitors of the importance of renewable energy. Today, we have for you the world’s largest solar powered creations that amaze us with their size and purpose they’re built for. Hit the jump to see them allWorld’s largest solar-powered office buildingThe world’s largest solar-powered building has been unveiled in Dezhou, Shangdong Province in northwest China.

The 75,000-square-meter office building is based on the sun dial structure and marks the urgency of seeking renewable energy to replace polluting fossil fuels. The building provides space for exhibition centers, scientific research facilities, meeting and training facilities and a sustainable hotel. Dubbed the Sun and the Moon Altar micro-row buildings, the architecture features the Chinese characters for sun and moon, while the white exterior symbolizes clean energy. In addition to a massive solar array, green ideas have been applied throughout the construction process. The external structure used only 1% steel for the Bird’s nest and advanced roof and wall insulation systems reduce 30% more energy than the national energy saving standard. The building will be the main venue for the 4th World Solar City Congress.World’s largest solar-powered footbridgePremier Anna Bligh has officially opened the world’s largest footbridge of its kind in Brisbane’s CBD. Constructed at a cost of over $63 million, the Kurilpa Bridge is expected to be used by about 36,500 people each week.

The structure is 470m long and more than 1050 people were employed on the project. Spanning the Brisbane River, the bridge employs a sophisticated LED lighting scheme that can be programmed to produce an array of different lighting effects, which will become a feature of Brisbane’s annual Riverfire celebrations. The energy-saving lighting system will be powered by 84 solar panels that collectively generate a daily output of about 100KWh and an average yearly output of 38MWh. The solar energy generates supplies 75% of the power required to run the LED setup in the fully lit mode, but in most lighting configurations, 100% of the energy required will come from the solar panels.

Surplus electricity generated by the solar array will be returned to the main grid.World’s largest solar powered trimaranPlanetSolar is a multi-hull vessel, commissioned by German investor Immo Stroeher. The vessel being built at a shipyard in Kiel, Germany is said to be the world’s largest solar-powered trimaran. It will not have sails; instead will rely on solar panels to circumnavigate the world in 140 days. The triple-hull, 30-metre-long, 15-metre-wide boat will incorporate solar cells onto the 508-square-metre top of the main centre hull. The solar panels are capable of producing 1,000 watts of electricity daily. Surplus energy is stored in the batteries, enabling the 58-ton trimaran to continue its journey without sun for up to three days at a speed of 10 knots or 18 kilometres per hour.World’s largest solar audio systemGrzebik Design has come out with what is being called the world’s largest solar powered loudspeaker system. Located in the Taiwan National Stadium in Kaohsiung, the audio system is capable of cranking out 105 dB of sound to 40,000 spectators.

The ultra-modern $5 billion Taiwan National Stadium features a stunning 14,155 square meter roof incorporating 8,844 solar panels, which emulates the form of a flowing river, and generates 1.14 million KWh annually preventing the release of 660 tons-per-annum of atmospheric carbon dioxide. The electricity generated is used to power the audio system. Designed by renowned Japanese architect Toyo Ito the whole system comprises of 60 distributed Apogee Sound AE-7SX weather-resistant loudspeakers for primary seating area coverage, 12 Apogee Sound ALA-5WSX weather resistant Acoustic Linear Array loudspeakers provides field coverage, and 2 Apogee Sound AFI-205 and two AFI-Point5 loudspeakers provide Control Room audio monitoring.World’s largest Solar Power Tower PlantAbengoa, a Spanish engineering company has developed a huge 54 story high tower near Seville in Spain.

Gaya Geser Dinamik Etabs Crack

Said to be the world’s largest solar power tower plant, it consists of more than 1200-mirrored heliostats neighboring a huge tower. Called the ‘PS20 plant’, the installation has heliostats covering 1291 ft2 area each, giving the entire heliostat field a massive area of 155,000 m 2. Each heliostat tracks the sun throughout the day on two axes and concentrates the radiation onto a receiver located on the upper part of the 531 ft tower. After this, the receiver converts 92% of received sunlight into steam that is piped down to a turbine driven generator at the base of the tower.

The PS20 plant is capable of generating 20 megawatts (MW) of electricity, enough to supply 10,000 homes.World’s Largest Solar ProjectTaking advantage of the dryness of Sahara Desert, renewable energy giants are prepping up the installation of the world’s largest solar power plant that collectively will generate a whopping 100GW of concentrating solar power. Promoted by Desertec Foundation, the plant will be built by 20 blue chip German companies, who would be gathering together to discuss plans and investments to create the massive project. Unlike other solar power plants, which are usually built on a single location, this massive plant would be scattered throughout politically stable countries in northern Africa.

The collective output of the plant would be 80 times larger than a similar plant being planned for the Mojave Desert. The power output would be transported across the Mediterranean Sea to Europe on high-voltage DC lines that will finally supply 15% of the energy demand.

The companies involved in the planning state that similar installations have to be constructed to end the gripping energy crisis. The €400bn project would take 10-15 years to go online, but once constructed it will help other countries of the world to aim towards renewable energy generating plants to end their dependence on fossil fuels.World’s largest solar powered treeBrisbane City Council have recently refurbished world’s largest solar powered Christmas tree to delight the Brisbane crowds. The beautiful tree has decked it out with new foliage, decorations and a sophisticated solar powered lighting system featuring 16,000 bulbs. Location in King George Square, the Christmas Tree features 250 red opaque baubles, a multicoloured twinkling light system and a giant star made up of solar panels for the tree’s top. The new-look tree would be more sustainable and help in saving the environment.World’s Largest Solar StadiumNo one has ever attempted to power an entire stadium with solar energy before, but Japan-based Toyo Ito Architects are using solar energy beyond all conventions to power the main stadium built for the World Games. The $150 million stadium can house 55,000 spectators and can power 80% of the surrounding neighborhood if it‘s solar array is connected to the grid during days when the stadium is not being used.

Every inch of the stadium’s incredible 14,155-sq-m roof area is covered with 8,844 solar panels that could potentially generate a whopping 1.14GWh of electricity annually. The record braking stadium is touted to be the world’s largest solar-powered stadium.World’s largest solar cooking systemIndia has been working on to escalate the use of solar energy in the country.

The country is boasting the development of the world’s largest solar steam cooking system that has been installed in Shirdi in the state of Maharashtra. The system, built at the cost of about $280,000 uses solar energy to convert water into 3,500kg of steam daily, which is then used to cook food for the pilgrims visiting the shrine of 19th century saint Sai Baba.

Gaya Geser Dinamik Etabs Tutorial

The system can feed up to 20,000 people per day and can save about 100,000kg of cooking gas annually. Of the total cost needed to install the system about 43% was paid by the government. The Chesapeake Bay Bridge-Tunnel ( CBBT) is a 23 mile long bridge and tunnel system that connects southeastern Virginia with Delmarva Peninsula in the United States. The bridge connects the following independent cities Virginia Beach, and Norfolk, Virginia to Cape Charles in Northampton County along the eastern shore of Virginia.The Chesapeake Bay Bridge-Tunnel uses a combo of tunnels and bridges over two separated shipping channels using four artificial islands built in the bay as portals.The bridge-tunnel was opened on April 15th, 1964, in August 1987 it was officially named the Lucius J. Bridge-Tunnel after one of the civic leaders who worked for its development. When the Spanish arrived in America and ultimately conquered the Aztecs, they erected their Christian temples atop their pyramids. Eventually their whole colonial city was built on top of the Aztec one.

In the 20th century, many colonial buildings were demolished and modern structures raised on the existing historic foundations. So in a way, Mexico City is like a massive layered cake: a modern metropolis built on the foundations of a colonial city that was erected on top of the ancient pyramids that were constructed on the lake.