What is horsepower? How do I calculate my horsepower? These are common questions we receive from our customers. To answer this question, let’s first define what horsepower is.Horsepower, like any unit of power, is simply a rate at which work is being done.

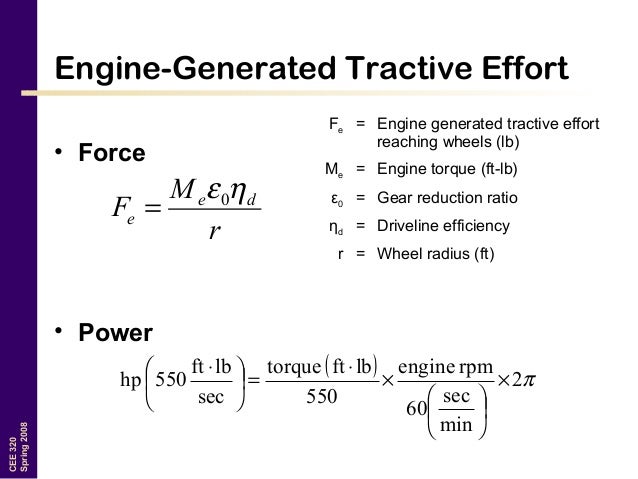

Literally, the horsepower unit originates from an experiment which set out to measure the power of a single horse. It was determined that a horse is capable of performing 33,000 ft-lbf of work per min. We will address to this number later in the explanation.First, a few equations to help you calculate your horsepower: Power = Work / Time Power = (Force x Distance) / TimeFor, power or horsepower can be calculated from the torque and speed. For example, if you have a motor rated for 3,000 RPM and 6 in-lbf then the horsepower is calculated below. Horsepower = (3,000 x 6) / 63,025 = 0.28663,025 is a constant when using RPM for speed and in-lbf for torque units. 5,252 is another common constant if the speed is in RPM and torque is in ft-lbf. If the units are different then simply make the unit conversion.The derivation of these constants is done using the 33,000 ft-lbf /min = 1 horsepower.

Though horsepower units are a derivative of the 33,000 ft-lbf/min, it is not critical to understanding how to calculate motor horsepower for speed and torque.Another common unit of power that motors are rated in is watts. The conversion from watts to horsepower is 745.7 watts = 1 hp.To assist designers with sometimes difficult unit conversions Groschopp has developed The, a free, downloadable program that provides a fast, easy way to calculate speed, torque, or power. Conversions of the most commonly used units are selectable, automatically generated and can be printed out.

Calculate Speed, Torque and Power. Calculate Estimated Electrical Current and Losses for Optimum Motor Selection. Easily and Accurately Convert Units of Measurement.

Customizable, Printed Report Function. Calculate Operating Costs. How to use the Motor Search ToolNarrow your search by selecting motor type, gearbox, voltage, and phase options for your desired motor. Yellow represents selected option. Dark gray represents available options. Light gray represents options not available with previously selected criteria.Select a dominant variable: choose one of the three parameters to narrow your search. The selected variable determines which slider bar you will be able to manually move.Use the slider corresponding to your dominant variable to further narrow your motor selection.

Plugging 4,600 rpm and 700 lb-ft into the torque/horsepower equation yields the result in Figure 3. At 4,600 rpm, a 700 lb-ft engine would already be making 613 hp. Theoretically, this combo would.

The other sliders will automatically move to show available ranges based on the range of your selected variable.Results will upload as your search criteria changes. If you have any questions regarding your results or how to use the search tool, you can chat with us using the green tab on the left-hand side of your screen.Note: Groschopp Universal motors are custom built to fit your application so no additional options are available to narrow the search. Selecting the Universal motor type will prompt a message taking you to the Universal product page.

Simplified FormulaCylinderArea - A(Sq. In.) = π × Radius (inch) 2A= π × R 2(Sq.In.) = π × Diameter (inch) 2/ 4A= π × D 2 / 4CylinderForce - F(Pounds)= Pressure (psi) × Area (sq.in.)F= P × ACylinderSpeed - v(Feet/ sec.) = (231 × Flow Rate (gpm)) /(12 × 60 × Area)v= (0.3208 × gpm) / ACylinderVolume Capacity - VVolume= π × Radius 2 × Stroke(In.) / 231V = π × R 2× L / 231(L = length of stroke)CylinderFlow Rate - QVolume= 12 × 60 × Velocity (Ft./Sec.) × NetArea(In.) 2 / 231Q= 3.11688 × v × AFluidMotor Torque - TTorque(in.

Lbs.) = Pressure (psi) × disp.(in. 3 / rev.) / 6.2822T= P × d / 6.2822Torque= HP × 63025 / RPMT= HP × 63025 / nTorque= Flow Rate (GPM) × Pressure × 36.77/ RPMT= 36.77 × Q × P / nFluidMotor Speed - nSpeed(RPM) = (231 × GPM) / Disp.(in.) 3n= (231 × GPM) / dFluidMotor Horsepower - HPHP = Torque (in. Lbs.) × rpm / 63025HP= T × n / 63025. Simplified FormulaPumpOutput Flow - GPMGPM= (Speed (rpm) × disp. In.)) /231GPM= (n ×d) / 231PumpInput Horsepower - HPHP= GPM × Pressure (psi) / 1714× EfficiencyHP= (Q ×P) / 1714 × EPumpEfficiency - EOverallEfficiency = Output HP / Input HPE Overall= HP Out / HP In X 100OverallEfficiency = Volumetric Eff. × MechanicalEff.E Overall= Eff Vol. × Eff Mech.PumpVolumetric Efficiency - EVolumetricEfficiency = Actual Flow Rate Output(GPM) / Theoretical Flow Rate Output(GPM) × 100Eff Vol.= Q Act.

/ Q Theo.X 100PumpMechanical Efficiency - EMechanicalEfficiency = Theoretical Torque to Drive/ Actual Torque to Drive × 100Eff Mech= T Theo. / T Act.× 100PumpDisplacement - CIPRDisplacement(In. 3 / rev.) = Flow Rate(GPM) × 231 / Pump RPMCIPR= GPM × 231 / RPMPumpTorque - TTorque= Horsepower × 63025 / RPMT= 63025 × HP / RPMTorque= Pressure (PSIG) × Pump Displacement(CIPR) / 2πT= P × CIPR / 6.28. GeneralFluid Power Guidelines:Horsepower for driving a pump:For every 1 hp of drive, the equivalent of1 gpm @ 1500 psi can be produced.Horsepower for idling a pump:To idle a pump when it is unloaded will requireabout 5% of it's full rated powerWattage for heating hydraulic oil:Each watt will raise the temperature of 1gallon of oil by 1° F. Per hour.Flow velocity in hydraulic lines:Pump suction lines 2 to 4 feet per second,pressure lines up to 500 psi - 10 to 15 ft./sec., pressurelines 500 to 3000 psi - 15 to 20 ft./sec.; all oil lines inair-over-oil systems; 4 ft./sec.

Torque Formula For Shaft

Torque (lb.in) = 63,025 x Power (HP) / Speed (RPM). Power (HP) = Torque (lb.in) x Speed (RPM) / 63,025. Torque (N.m) = 9.5488 x Power (kW). Other Units: Estimate of engine horsepower after a quarter mile run using the trap speed method. Determine the increase in engine horsepower when an after market modification, race or performance part has been installed with trap speed. Calculate engine horsepower after a quarter mile run using the ET method.